Tote Bag

Shinshu Kosuzume

from BRIEFING

2019.03.20

VOL.08

Find out little-known yet interesting facts about clothing through the words of discerning designers who have been creating

essential masterpieces for BEAMS PLUS collections.

The crucial new philosophy of BEAMS PLUS,

“Updating timeless classics for the future,” cannot be achieved without their wealth of knowledge.

vol.08

Tote Bag

Shinshu Kosuzume

from BRIEFING

Shinshu Kosuzume (Designer of BRIEFING)Born in 1966, Kosuzume worked as a designer at a major bag manufacturer before joining Sellts Limited (now in Union Gate Group) in 1999. While designing bags for their WRAPS brand and other OEM labels, he participated in the launch of BRIEFING as its main designer. He has designed over 400 models for the brand’s Made in the U.S.A. line all by himself, producing a series of bestselling items. Kosuzume currently works as the manager of the design room at the company’s creative head office with four junior staff.

Our tote bag was gradually accepted

because of the advanced design

with Mil-Spec quality.

A tote bag was originally

made to allow

the user to put

anything in it and then toss it in

a car boot. It’s very American.

“Around the time when I first joined the industry about 30 years ago, bag manufacturers in the world, except a few prestigious ones, didn’t really make fashionable bags. There were only business briefcases or sports/outdoor bags in the market. In that sense, I may be able to say that Japanese manufacturers were well ahead of the time. Although train commuters in Japan needed functional, light-weight and durable bags, people of the time considered tote bags as something made for women because it looked like paper shopping bags. And many of tote bags made before then were not self-standing, I think.”

“L.L.Bean’s canvas tote bags were one of the exceptions. The item became popular among young students between the 1970s and the 1980s after being introduced to Japan as a part of the Ivy League style. However, it was initially made for outdoor use as the very first model of a tote bag. The design allows the user to put anything in it and then toss it in a car boot. It’s very American. I think it’s a great example of smartening up a simple design with the use of bold colors.”

Our early masterpiece innovated

the idea and use of tote bags.

30 years ago, there was no

self-standing tote bag

that neatly

accommodates paper documents.

“BRIEFING has been producing tote bags since the very beginning. Our fist model is called Collection Tote and the design was inspired by a shotgun case. I wanted to make a self-standing briefcase by resizing the masculine tool, so that men could also bring tote bags, I thought. Because there was no tote bag that neatly accommodates paper documents by then, our design was truly innovative though it is very common now. People never brought tote bags for work 30 years ago, as leather briefcases were usually used. Leather ones look nice, but heavy to carry. It gains even more weight as you put documents in it. Just like 3-way bags that becomes popular lately, tote bags had been naturally accepted by business people according to the changes of their equipment, styles and ways to work.”

The appearance of a bag is changed by the handles.

The brand’s early tote bags feature iron rectangle slides,

but business people of the time were not satisfied with

the finishing because it gets tarnished with use.

The brand developed their own matte die-cast rings.

The low-key design has something in

common with military clothing.

* Rectangle slide: A metal slide in a rectangle shape.

* Swivel clasp: A metal hook that whirl.

* Die casting: A metal casting process accomplished by forcing molten metal under high pressure into reusable metal dies.

“The difference between a tote bag and a briefcase is the way it is used, and the length of the handles is crucial in the design of each bag. Shorter handles are easier to use, but not enough to fit over your shoulder. On the other hand, longer handles cannot hold the body of a bag firmly, while the body may reach the ground when you hang it from your hand. Handles and detailing around it are so important in bag-making that it is often said that the overall design of a bag depends on those elements. BRIEFING has been using a certain width belt and a rectangle slide for its product since long ago. Although the bag was not designed for a business person, we changed the original military-like durable iron slide to our exclusively developed die-cast ring to make the product look better with suit and jacket styles, because iron slides can get rusted with continuous usage. Another reason we changed the material was a die-cast swivel clasp we used. As it directly connected to the slide, we needed to use the same material. If we use different materials for those, the weaker one may wear out faster than the other.”

“We use YKK zippers for our products. The company’s zippers are also used for military gear and equipment because such life-saving devices should be made with reliable parts. There are some old-school zipper manufacturers also in the U.S., but what we need is tough, durable products that can be repeatedly opened and closed. If we use an iron one for a bag, the surface can be worn off just like a rectangle slide we used. We always think it is important to choose parts and materials according to how the product is used.”

* Rectangle slide: A metal slide in a rectangle shape.

* Swivel clasp: A metal hook that whirl.

* Die casting: A metal casting process accomplished by forcing molten metal under high pressure into reusable metal dies.

Some of the BRIEFING collections have been made in the U.S. since the brand’s establishment.

A munitions factory producing specialty bags manufactures their products.

According to Kosuzume, the creative commitment

of the brand can be seen on seams.

American factories make a product

practically,

while manufacturers

in Japan stick to efficiency.

“I have stuck to manufacture our products in the U.S. And I do think the idea of manufacturing in the country is quite different from the one in Japan or China. In America, the manufacturing cost rises as the number of operation processes increases, because the way of production in the country is reasonable. They think a product made from a piece of cloth is more durable with less seams. Contrarily, Japanese and Chinese manufacturers tend to focus on using fabric more efficiently. So, the products made in those countries tend to be intricate. BRIEFING’s bags are made at a munitions factory at which even the slightest mistake can be fatal. Therefore, their products are made not to be broken. Working with such a manufacturer is a big advantage for us, I think. And our mission is to integrate their techniques into the Japanese market as products that can be used in real-life situations. Military gear is not designed for everyday use, even though it is stylish enough as a fashion item. People, especially men, won’t go on using a bag if it is not practically designed regardless of whether it looks stylish or not. We have been continuously updating our design, while incorporating materials that fit naturally into the Japanese lifestyle and taking advantage of Mil-Spec products. In a sense, it can be said that bags are used more harshly in Japanese rush-hour trains than in battlefields.”

The Air Force blue color is

reminiscent of the United States Air Force’s flight jacket.

This Cordura fabric in a color named “Foliage” was exclusively developed 10 years ago.

The original lining cloth was in emergency orange.

“Our latest item made exclusively for BEAMS+ (BEAMS PLUS) can be called the culmination of our 20-year bag-making, because all the fabrics of this bag, Ballistic nylon and 500- and 1000-denier Cordura, are the ones we’ve used in the past. This army-gray color is named ‘Foliage’ and was originally developed for an exclusive item to celebrate the 10th anniversary of the brand. The color had been well-received by our customers, so we decided to adopt it again. Of course, we tried to use it in a meaningful way, placing the right material in the right place.”

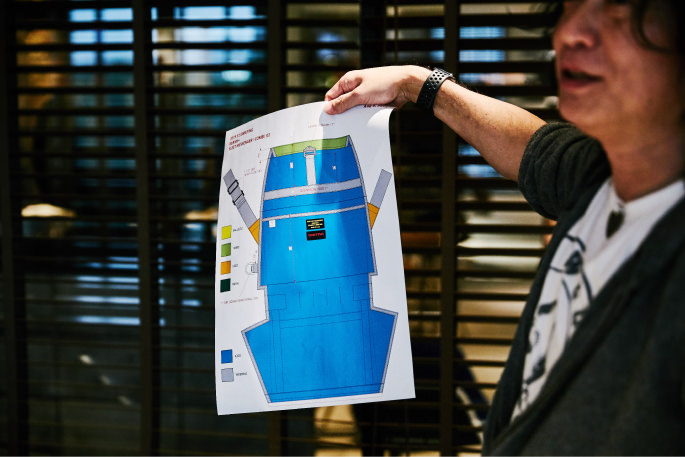

The design sheets of the brand’s bag made exclusively

for BEAMS+ to commemorate its 20th anniversary.

- Edit & Writing : Masayuki Ozawa

- Translation: Aya takatsu

- Photography : Dai Yamamoto

- Illustration : Naoki Shoji

- Design and Development : maam.inc

BRIEFING × BEAMS PLUS

(Left) CRAZY Fleet Messenger /

Color : CHARCOAL GREY, BLACK, NAVY / Price : ¥24,000+tax(Center) CRAZY Helmet Bag /

Color : CHARCOAL GREY, BLACK, NAVY / Price : ¥56,000+tax(Right) CRAZY 3WAY Bag /

Color : CHARCOAL GREY, BLACK, NAVY / Price : ¥56,000+tax

The products shown in this article are

available at BEAMS PLUS stores.

BEAMS PLUS YURAKUCHO / BEAMS MEN SHIBUYA /

BEAMS TSUJIDO / BEAMS UMEDA / BEAMS KOBE

vol.15

American Suit

Hisao Saito

from TUBEvol.14

BACKPACK

Takao Fujimoto

from STANDARD SUPPLYvol.13

5 Pocket Denim Pants

Kenichi & Koji Shiotani

from WAREHOUSEvol.12

Luggage Wear

Setsumasa Kobayashi

from .....RESEARCHvol.11

Leather Wallet

Daisuke Motoike

from MOTOvol.10

Fatigue Pants

Daiki Suzuki

from ENGINEERED GARMENTSvol.09

Tie

Kenichi Kusano

from KENNETH FIELDvol.08

Tote Bag

Shinshu Kosuzume

from BRIEFINGvol.07

Coverall Jacket

Takeshi Ohfuchi

from Post O'Allsvol.06

Balmacaan Coat

Shinsuke Kojima

from KAPTAIN SUNSHINEvol.05

Western Shirt

Yutaka Goto

from REMI RELIEFvol.04

M-51

Kimitoshi Chida

from sage de cretvol.03

Sweat

Satoshi Suzuki

from LOOPWHEELERvol.02

Open Collar Shirt

Hirofumi Yamashita

from MOJITOvol.01

Blazer

Jack Carlson

from ROWING BLAZERS